Projects within the DFG Priority Program 2045

Contact: Dr.-Ing. Bernd Benker

The CUTEC Research Center is involved in two basic research projects within the DFG Priority Program 2045 "Highly Specific Multidimensional Fractionation of Technical Fine Particle Systems", which aim to classify fine particles according to their size and sort them according to their material type. The work started in 2017 and is now in the second three-year research phase.

Project participants are:

- Prof. Alfred Weber, IMVT, applicant, lead.

- Dr. Bernd Benker, CUTEC, applicant

- M.Sc. Juliana Ribas-Botero, project leader

- M.Sc. Leonard Hansen, project leader

- Prof. Gunther Brenner, ITM, support of flow simulation

- M.Sc. Thorben Settgast, ITM, CFX modelling

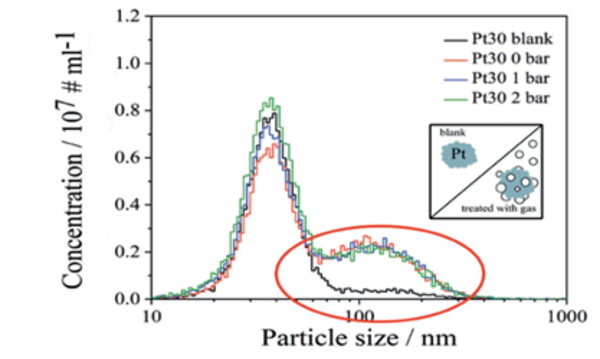

In the project "Nanobubble-induced centrifugal field flotation of nanoparticles", M.Sc. Juliana Ribas-Botero is striving to further develop the dissolved air flotation previously used for water purification into a substance-specific separation process in the ultra-fine range. Up to now, the formation of bubbles on the particle surface, which is crucial for flotation, has been systematically investigated for 50 nm "large" nanoparticles using an optical measuring device (principle: particle tracking, i.e. observation and evaluation of the diffusion of individual particles) (see Fig. 1). The comparison of platinum and gold nanoparticles showed that the roughness of the surface plays a major role. With regard to the application, it was thus shown that a substance-specific separation is possible even for these very small particles. Following these successful investigations on ideal, highly diluted substance systems, practical investigations are now on the agenda in the second funding phase.

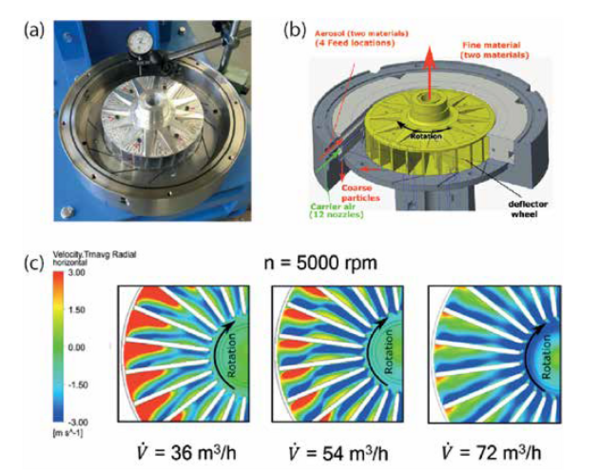

In the second project with CUTEC participation, M.Sc. Leonard Hansen has designed, built and put into operation a "sharp deflector wheel air classifier for the dry fractionation of submicron particles" in the first project phase. It has a modular design in order to enable an optimization of the geometry in the interplay of experiment and flow simulation (with CFX) in the further course of the project. In addition, the electrostatic side effects, which are usually regarded as disturbing, will be intensively investigated in order to use them for sorting.

Wind sifting and electrostatic sorting have long been used industrially for coarse-grained materials (compared to nanoparticles). The progress being made in this project is aimed at pushing the application limits of these methods so far into the fine range that a separation and sorting technique beyond the laboratory scale is also available in the nanometre range.

The complex structure of the classifier required a 3-dimensional flow model and a transient calculation on the high-performance computer network HLRN. The results show, among other things, that the size of the disturbing vortex regions depends on the operating parameters.