Circularity of the electric drivetrain through intelligent disassembly and tracking

The automated disassembly of end-of-life products makes it possible to return valuable components, assembly groups and materials to the circular economy more efficiently than traditional recycling routes. This not only achieves goals of ecological importance for the circular economy, it also compensates for supply bottlenecks for critical raw materials by means of fewer dependencies.

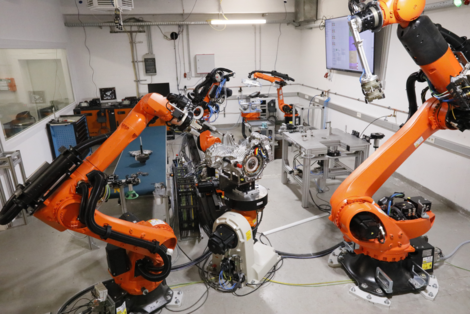

The CUTEC research center as part of the TU Clausthal operates a technical pilot plant in which electric drive units are dismantled using modern robot, camera and sensor technology. Specially designed tools are used to enable the non-destructive removal of components. Product design represents a particular challenge and addresses a main research topic in the Project ZirkulEA - How are the components connected to each other? How challenging are the single process steps of a fully automated disassembly? From this experience, design-for-recycling guidelines can be derived as a decisive step towards a circular economy.

Duration: 01.10.2022 – 30.09.2025

Funded by Federal Ministry of Education and Research

Link to BMBF:

LinkedIn:

Contact

Dipl.-Inf. Sven Birkenfeld

Research Assistant

Group Manager Digitalization and Automation

Phone: +49 5323 72-6471

E-mail: sven.birkenfeld@cutec.de