Pressure drop and temperature profile measurements on a pilot-scale fixed-bed reactor.

Contact: Dr.-Ing. Marina Bockelmann

The fixed-bed reactor is the most commonly used reactor type for heterogeneously catalyzed fluid-solid reactions. In this process, the catalyst used is applied to differently shaped, usually ceramic support structures and poured into a tubular reactor, creating the fixed bed of particles. The advantage of such fixed-bed reactors is the effective cooling of the reactor via the outer wall, especially in the case of highly exothermic reactions. In order to realize a sufficiently large contact area between the reactor and the cooling medium, the diameter of the reactor tubes is reduced to a few centimeters. In the chemical industry, up to several tens of thousands of such tubes are combined into a bundle. However, the complexity of the design due to the large number of tubes increases the cost of such apparatus.

An innovative approach to improve the heat transfer in a tubular reactor is the use of open-pored metallic catalyst supports, so-called metal sponges. Since metals have a much higher thermal conductivity than ceramics, the radial heat transfer in fixed-bed reactors can be increased by using metal sponges. Accordingly, the diameter of the tubes can be enlarged, their number in the bundle can be reduced and thus costs can be lowered.

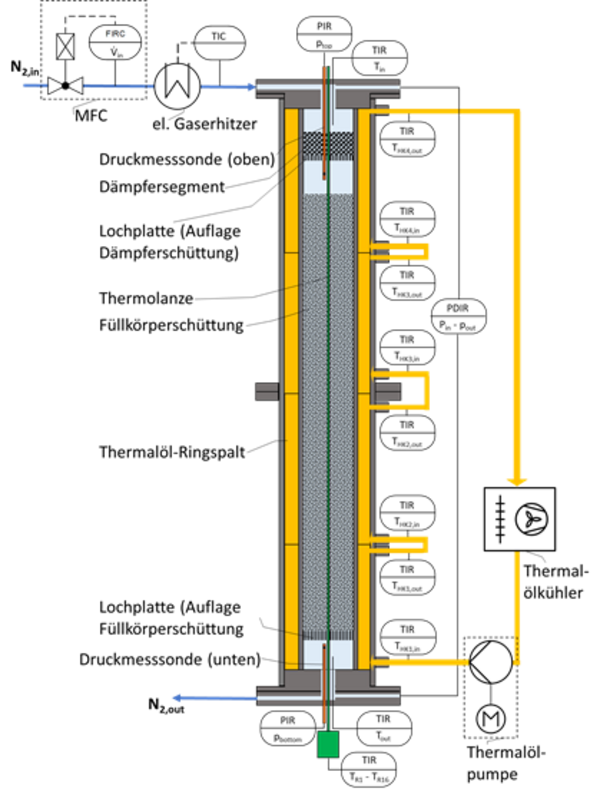

As part of a ZIM project "Innovative development process for optimal foam pellets as catalyst carriers for fixed-bed reactors", the working group of Prof. Wehinger from the Institute of Chemical and Electrochemical Process Engineering at the Clausthal University of Technology (ICVT) is working together with Alantum Europe GmbH to analyse the fluid-dynamic behaviour of fixed-bed reactors and map it using CFD simulations in order to determine the optimal properties of the metal sponges for a reactor bed. The experimental work necessary for the validation of the CFD models is carried out on a 2500 mm high tubular reactor with a diameter of 69 mm by the Chemical Energy Systems group at the CUTEC Research Centre. Thereby, the pressure drop of the bed to be investigated is measured over four different zones. Furthermore, a steady-state temperature profile of the reactor is recorded via 16 temperature measuring points centrally integrated in the fixed particle bed.