CO2OL - Synthesis of linear alpha-olefins from CO2

Contact: M.Sc. Niko Theunißen

Olefins such as ethene, propene and butene are starting materials for the production of many basic materials of the chemical industry such as polyethylene (PE) or polypropylene (PP). The current extraction of olefins is based on fossil raw materials and is associated with high emissions of climate-damaging gases.

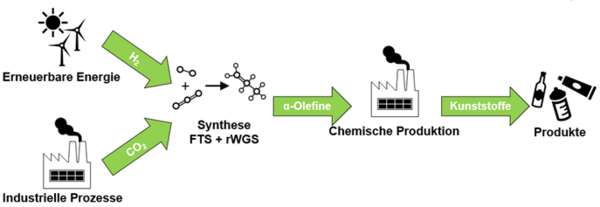

The joint project "CO2OL - catalyst, reactor and process development for the direct synthesis of linear alpha-olefins from CO2" has set itself the goal of demonstrating an alternative, climate-friendly production process. To this end, an olefin production route based on CO2 and hydrogen is being investigated. Waste gas streams from the cement industry or biogenic sources such as biogas can be used as CO2 sources. The hydrogen required can be generated in a climate-friendly manner by means of water electrolysis from renewable electricity.

The core of the technological concept is the Fischer-Tropsch process, in which a paraffin/olefin product mixture is synthesized from synthesis gas. By modifying the catalyst system, this process is to be coupled with the reverse water gas shift reaction. In this way, CO2 can be used directly as a reactant without prior synthesis gas production.

Within the scope of the project, both the catalyst system, an innovative, scale-up-capable synthesis reactor, the separation process for the paraffin/olefin product mixture by means of a membrane process and the conception, testing and optimisation of the overall process are to be investigated and optimised. The process is to be implemented during the project period in the form of a miniplant plant. In addition to the technical implementation, an evaluation of the overall process based on the CO2 savings potential and economic factors will be carried out by means of process simulations.

Further information: